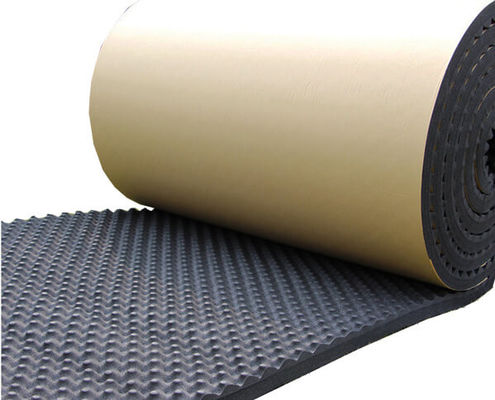

Chất chống ẩm mềm EPDM cuộn cao su Back cho máy gia dụng

Thông tin chi tiết sản phẩm:

| Nguồn gốc: | Được làm ở Trung Quốc |

| Hàng hiệu: | EkkoFlex |

| Chứng nhận: | ROHS,REACH |

Thanh toán:

| Số lượng đặt hàng tối thiểu: | 3000㎡ |

|---|---|

| Giá bán: | $0.8-1.89/㎡ |

| chi tiết đóng gói: | túi poly hoặc tùy chỉnh |

| Thời gian giao hàng: | 7-14 ngày làm việc |

| Điều khoản thanh toán: | T/t, l/c |

| Khả năng cung cấp: | 1000000m mỗi tháng |

|

Thông tin chi tiết |

|||

| Tên sản phẩm: | Kháng độ ẩm mềm EPDM Cuộn cao su cuộn trở lại cho máy gia dụng | Vật liệu: | Ethylene-propylene-diene monome |

|---|---|---|---|

| Cấu trúc tế bào: | Đóng Bọt EPDM và Bọt EPDM tế bào mở | Mật độ (ô mở): | 95-100kg/m³ |

| Mật độ (tế bào đóng): | 110-150kg/m³ | Tính năng: | Bộ đệm đàn hồi cao, điện trở nhiệt độ, điện trở lửa |

| Ứng dụng: | Máy gia dụng; niêm phong cho thiết bị điện tử | Màu sắc: | Đen |

| Độ dày: | 1-50mm | Kích thước tối đa: | 1000*2000*50mm |

| Làm nổi bật: | Băng keo mặt sau cao su EPDM,Xốp EPDM chống ẩm,Gioăng cao su máy móc gia dụng |

||

Mô tả sản phẩm

Cuộn cao su EPDM chịu ẩm mềm có mặt sau dính cho máy móc gia dụng

Bọt EPDM có khả năng chống chịu thời tiết, ozone, ăn mòn, chịu nhiệt, ổn định và cách nhiệt, cách nhiệt, đệm, hấp thụ sốc, cách âm, bịt kín và chống cháy tuyệt vời. Các sản phẩm EPDM có thể được sử dụng ở nhiệt độ từ -40°C đến 120°C. Bọt EPDM được sử dụng rộng rãi trong các ngành công nghiệp như máy móc, niêm phong, ô tô, điều hòa không khí, điện tử, xây dựng, dụng cụ, hàng không và các thiết bị nhỏ.

Bọt CR, còn được gọi là cao su chloroprene, thể hiện các đặc tính vật lý và cơ học tuyệt vời, bao gồm khả năng chống dầu, nhiệt, ngọn lửa, ánh sáng mặt trời, ozone, axit, kiềm và hóa chất. Nó cũng thể hiện độ bền kéo và độ giãn dài cao, độ kết tinh có thể đảo ngược và độ bám dính tuyệt vời.

Công dụng tốt nhất của Neoprene (CR):

Ô tô: CR được sử dụng rộng rãi trong đường ống nhiên liệu, phớt, miếng đệm và ống mềm yêu cầu khả năng chống dầu và nhiên liệu tuyệt vời.

Công nghiệp: CR cũng được sử dụng trong các ứng dụng công nghiệp yêu cầu khả năng kháng hóa chất, chẳng hạn như phớt và miếng đệm công nghiệp.

Y tế: Khả năng chống cháy và khả năng tương thích sinh học của CR khiến nó trở thành vật liệu được ưa chuộng cho các thiết bị y tế như găng tay, ống thông và mặt nạ.

Công dụng tốt nhất của EPDM (Monome Ethylene Propylene Diene):

Ô tô: Do khả năng chống tia cực tím và ozone, EPDM thường được sử dụng trong các dải thời tiết, phớt và miếng đệm cho các bộ phận ô tô.

Xây dựng: EPDM thường được sử dụng trong vật liệu lợp và phớt ngoài trời do khả năng chống chịu thời tiết và độ ổn định tia cực tím tuyệt vời.

Ống: EPDM được sử dụng trong ống và miếng đệm thường xuyên tiếp xúc với nước và hơi nước.

Thông số kỹ thuật:

Tính chất vật lý của EPDM (Ô kín):

| Tên&Mẫu | Màu sắc | Mật độ (kg/m³) |

Độ cứng (Shore C°) |

Độ bền kéo (Kpa) |

Độ giãn dài (%) |

Biến dạng nén (%) |

Độ bền xé (kn/m) |

Kích thước (mm) | Ghi chú |

| EPDM-9016 | Đen | 190±15 | 25°±5 | ≥500 | ≥130 | ≤40 | ≥3.0 | 950*1900*40 | |

| EPDM-9015 | Đen | 150±15 | 15°±5 | ≥400 | ≥120 | ≤45 | ≥2.0 | 1000*2000*50 | |

| EPDM-9010 | Đen | 130±15 | 10°±3 | ≥350 | ≥120 | ≤35 | ≥1.8 | 1000*2000*50 | |

| EPDM-9008 | Đen | 110±15 | 8°±3 | ≥350 | ≥120 | ≤35 | ≥1.8 | 1000*2000*50 | |

| EPDM-WS | Đen | 150±15 | 15°±5 | ≥400 | ≥120 | ≤40 | ≥2.0 | 1000*2000*50 | Không chứa lưu huỳnh |

| EPDM-GBZ | Đen | 250-500 | 30°-50° | ≥800 | ≥130 | ≤20 | ≥5.0 | 900*1800*35 | Mật độ cao |

| EPDM-GYD | Đen | 600-700 | 50°-75° | ≥1200 | ≥90 | ≤10 | ≥8.0 | 600*1200*30 | Độ cứng cao |

| EPDM-SMP | Đen | 300±25 | 18°±5 | ≥500 | ≥150 | ≤25 | ≥2.0 | 400*500*568 | Vỏ hai mặt |

Tính chất vật lý của EPDM (Ô hở):

| Tên&Mẫu | Màu sắc | Mật độ (kg/m³) |

Độ bền kéo (Kpa) |

Độ giãn dài (%) |

Biến dạng nén (%) |

Độ bền xé (kn/m) |

Kích thước (mm) | Ghi chú |

| EPDM-10 | Đen/Đỏ/Trắng | 100±15 | ≥100 | ≥200 | ≤3.1 | ≥0.5 | 1000*2000*60 | |

| EPDM-10Z | Đen/Đỏ | 100±15 | ≥100 | ≥200 | ≤3.1 | ≥0.5 | 1000*2000*60 | Chống cháy |

| EPDM-20 | Đen | 85±15 | ≥100 | ≥200 | ≤3.1 | ≥0.5 | 1000*2000*30 |

![]()

Sự khác biệt giữa EPDM, NBR và bọt cao su CR:

| So sánh các thông số hiệu suất của bọt cao su | |||

|

Hiệu suất |

Bọt cao su EPDM |

Bọt cao su NBR |

Bọt cao su CR |

|

Kháng lão hóa |

tốt |

kém |

tốt |

|

Cách điện |

rất tốt |

kém |

kém |

|

Chất bảo quản |

tốt |

chung |

tốt |

|

Độ đàn hồi va đập |

tốt |

chung |

-- |

|

Tính chất kết dính |

kém |

tốt |

-- |

|

Kháng dầu |

không |

rất tốt |

tốt |

|

Kháng mài mòn |

tốt |

tốt |

-- |

|

Chịu nhiệt |

rất tốt |

tốt |

tốt |

|

Kháng lạnh |

rất tốt |

kém |

kém |

|

Kháng ozone |

tốt |

-- |

tốt |

|

Kháng thời tiết |

rất tốt |

chung |

rất tốt |

|

Khả năng chống cháy |

không |

-- |

tốt |

|

Kháng axit |

tốt |

tốt |

chung |

|

Kháng kiềm |

tốt |

tốt |

tốt |

Câu hỏi thường gặp:

Q1:Bạn có chấp nhận các sản phẩm bọt tùy chỉnh không?

Chúng tôi có dịch vụ sản xuất tùy chỉnh, chúng tôi có thể sản xuất các sản phẩm bọt theo yêu cầu của khách hàng.

Q2:Tấm bọt cao su là gì?

Một tấm cao su là một vật liệu phẳng, linh hoạt được làm từ cao su tự nhiên hoặc tổng hợp, được sử dụng trong nhiều ứng dụng công nghiệp, thương mại và DIY để bịt kín, cách nhiệt, giảm rung và bảo vệ.

Q3: Các loại tấm cao su nào có sẵn?

Các loại phổ biến bao gồm: Cao su tự nhiên – Độ đàn hồi cao và khả năng chống rách.

Neoprene (CR) – Chống dầu, thời tiết và chống cháy. Nitrile (NBR) – Chống dầu và nhiên liệu.

EPDM – Khả năng chống tia cực tím, ozone và thời tiết tuyệt vời.

Cao su silicon – Khả năng chịu nhiệt độ cao.

SBR (Cao su Styrene-Butadiene) – Sử dụng chung

Q4:Làm thế nào để lấy mẫu?

Gửi yêu cầu đến cissy@eco-polyfoam.com, với thông tin chi tiết về các loại bọt cần thiết, chúng tôi sẽ kiểm tra trả lời trong 24 giờ